Speed:80-100pcs/min

Cups Size: 2.5-22 oz Customized max 32oz

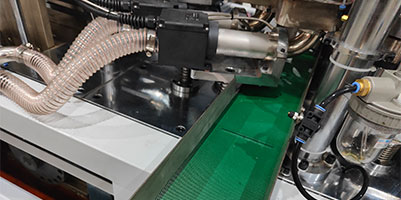

The RD-12/22-100A machine formed paper cups by two turntables. It using open intermittent indexing mechanism,gear transmission,vertical axis structure,Adopting an open intermittent indexing mechanism, gear transmission, and longitudinal axis structure, various functional assemblies are reasonably distributed.

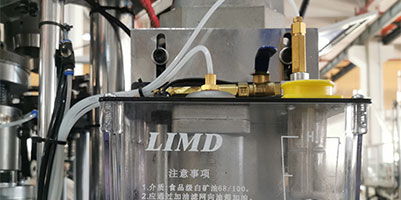

The whole machine adopts the way of oil lubrication to reduce the wear of machine parts.

The wall of the cup is heated by Swiss Leister hot air heater to ensure the stability of the bonding.

And the bottom of the cup is also bonded by Swiss Leister hot air heater.

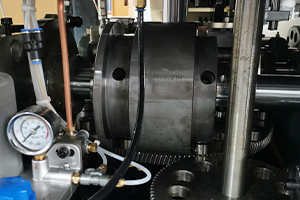

The two-step cup edge curling: 1. the first rotating winding 2. the second heating and shaping making the paper cup forming strength is improved,the rolling mouth is beautiful and the size is stable.

The whole forming process use PLC control, it use photoelectric eye fault monitoring and the servo control feed to improve the performance of the equipment. So the machine can achieve fast and stable operation, automatic shutdown in case of malfunction, greatly reduced the working intensity of labors and improved the safety and stability of the equipment.

By simplifying the process of cup making, the machine concentrate paper fan feeding, cup wall bonding,bottom paper feeding,cup loading,heating, cup bottom folding, cup bottom knurling,cup edge curling,cup unloading,detection,automatic counting and cup collection in one. It is the best choice for making paper cups.