In today's era of environmental protection and sustainable development, a variety of innovative technologies and equipment are constantly emerging to bring positive changes to our lives and the environment. Today, we will take an in-depth look at an equipment of great significance -- Non Plastic Coating Machine.

What is Non Plastic Coating Machine?

Non Plastic Coating Machine is an advanced machine specially designed to apply non-plastic coatings to surfaces. It is designed to reduce the use of traditional plastic coatings, which are difficult to degrade in the natural environment and have a long-term negative impact on the ecosystem. This non-plastic coating machine employs special processes and materials to provide high-quality coating protection for products while being environmentally friendly.

The Non Plastic Coating Machine works on the basis of advanced physical and chemical technology. Firstly, it evenly sprays or rolls specially formulated non-plastic coating materials onto the surface of the object to be treated. These coating materials usually consist of environmentally friendly biodegradable substances such as natural resins, water-based paints, etc. The coating material is then applied by a series of heating and curing processes. Then, through a series of heating, curing and other process steps, the coating is tightly bonded to the surface of the object to form a strong, durable and environmentally friendly protective film. During the whole process, the equipment will accurately control the thickness, uniformity and other parameters of the coating to ensure that the quality and performance of the coating is optimal.

Advantages of Non Plastic Coating Machine

1. Excellent environmental protection

The extensive use of traditional plastic coatings has led to serious plastic pollution problems, posing a great threat to soil, water bodies and biodiversity.The non-plastic coating materials used by Non Plastic Coating Machine are biodegradable and will not accumulate in the environment, greatly reducing the negative impact on the environment. This not only helps to protect our ecological environment, but also meets the global environmental protection trend and regulatory requirements, providing strong support for the sustainable development of enterprises.

2. Excellent performance

Non Plastic Coating does not mean compromising on performance. On the contrary, products treated with Non Plastic Coating Machine are coated with excellent abrasion, corrosion and weather resistance. This protects the surface from the elements and extends the life of the product. Whether in harsh outdoor environments or complex industrial production conditions, Non Plastic Coating can show excellent performance and ensure the quality and reliability of products.

3. Wide range of applications

This equipment has a wide range of applications. In the food packaging industry, it can provide environmentally friendly coatings for paper boxes, cans, etc., which not only ensures food safety, but also reduces the use of plastic. In the field of electronic products, Non Plastic Coating Machine can provide beautiful and durable non-plastic coatings for mobile phone shells, computer accessories, etc., to enhance the texture and competitiveness of products. In addition, in the furniture, building materials, automotive and other industries, it also has a broad application prospect, providing a feasible solution for product upgrading and environmental transformation in various fields.

4. Cost-effective

Although the initial investment of Non Plastic Coating Machine may be relatively high, in the long run, it has significant cost-effectiveness. On the one hand, with increasingly stringent environmental requirements, companies using traditional plastic coatings may face more and more restrictions and increased costs, such as environmental taxes and waste disposal fees. These additional costs can be avoided by adopting Non Plastic Coating Machine. On the other hand, due to the excellent performance of Non Plastic Coating, it can reduce the wear and tear and maintenance cost of the products, improve the production efficiency, and thus bring more economic benefits to the enterprises.

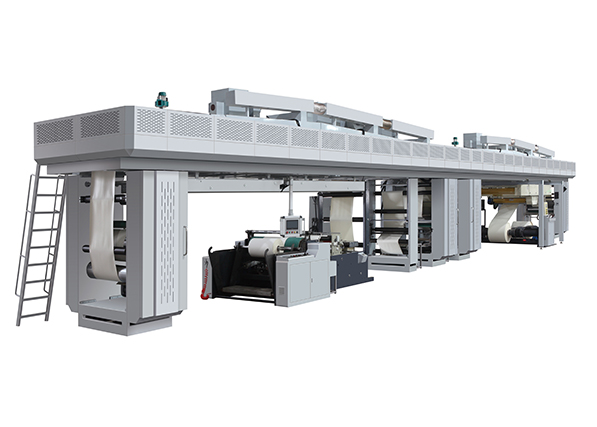

The Ruida Non Plastic Coating Machine has an advanced control system and excellent performance parameters. The machine is controlled by 4 variable frequency motors and the tension of the whole machine (including coating, oven, haul-off, winding, etc.) is automatically controlled by a PLC system, with the help of a human-machine interface touch screen for control and display, which greatly improves the reliability of the tension of the whole machine. The machine performs very well in terms of important parameters, with speeds of 70 - 80 m/min, a maximum sheet width of W 1100 mm, automatic slice winding and unwinding for sheet thicknesses of 30 - 350 g, an oven length of 10 m², and a circulating electric heating mode. This machine shows high efficiency, precision and stability in the field of coating processing, and provides reliable technical support and guarantee for the relevant production. Whether in terms of production efficiency or product quality, can meet the high standards of production needs, help enterprises to enhance competitiveness, to achieve high-quality production operations.

Non Plastic Coating Machine, as an innovative and forward-looking technical equipment, provides us with a brand new coating solution with its advantages of environmental protection, high performance, wide range of applications and cost-effectiveness. It is not only the embodiment of technological progress, but also our positive response to environmental protection and sustainable development. Let's all look forward to it playing a greater role in the future and bringing more benefits to our lives and our home planet.